AI Application in Manufacturing

Artificial Intelligence (AI) is revolutionizing the manufacturing industry by optimizing operations, improving productivity, and enhancing decision-making processes. With advancements in machine learning and robotics, AI technologies are transforming traditional manufacturing processes, boosting efficiency, and paving the way for a smarter and more connected future.

Key Takeaways:

- AI is revolutionizing the manufacturing industry by optimizing operations and enhancing decision-making processes.

- Machine learning and robotics advancements are transforming traditional manufacturing processes.

- AI technologies boost efficiency and pave the way for a smarter and more connected future.

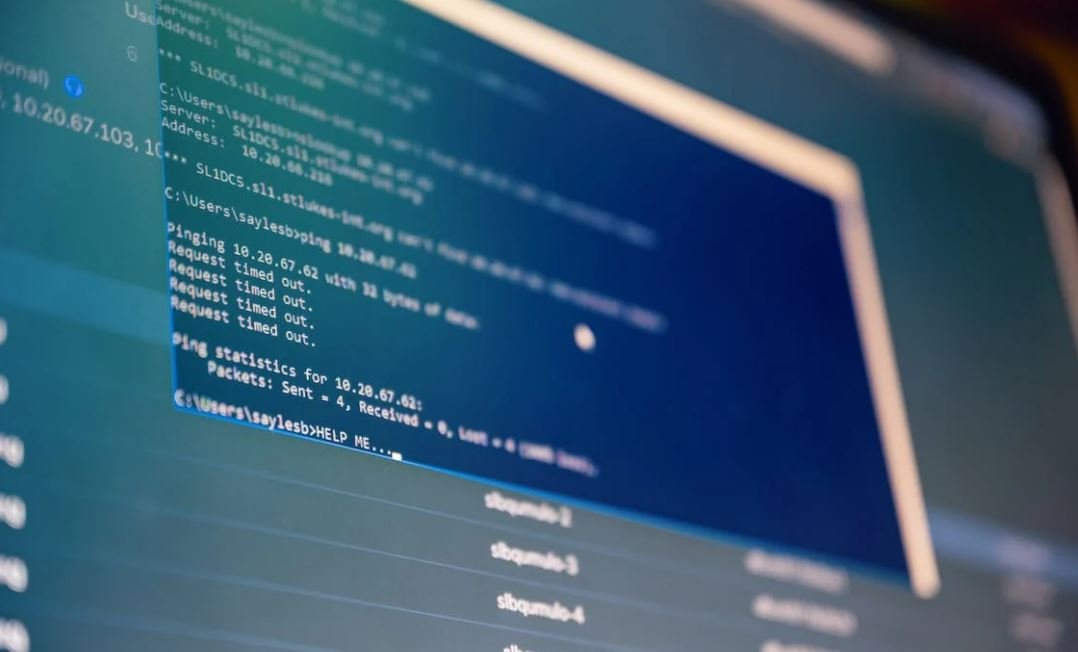

**AI algorithms** are employed in manufacturing to perform **predictive maintenance**, identifying potential machinery failures before they occur. These algorithms analyze vast amounts of historical data and real-time sensor readings to detect patterns and anomalies, enabling manufacturers to schedule timely maintenance, reduce downtime, and prevent costly breakdowns. *Predictive maintenance powered by AI can save businesses significant costs associated with unplanned downtime and repairs while facilitating seamless production processes.*

AI-powered **computer vision systems** have become integral to quality control processes in manufacturing. These systems use cameras and deep learning techniques to inspect and detect defects in real time, ensuring that only high-quality products reach the market. *With computer vision, manufacturers can achieve better product quality and reduce the risk of defective items reaching end-users, thus protecting their brand reputation.*

| Company | Annual Savings (USD) |

|---|---|

| Company A | 5,000,000 |

| Company B | 3,800,000 |

| Company C | 2,200,000 |

AI-powered **robotics** are increasingly being used in manufacturing environments to automate repetitive and hazardous tasks. These robots can perform tasks with great precision, speed, and consistency, reducing human error and increasing overall productivity. *By harnessing AI to automate their processes, manufacturers can free up human resources for more complex and value-added tasks.*

| Company | Defect Reduction (%) |

|---|---|

| Company X | 75% |

| Company Y | 60% |

| Company Z | 80% |

By leveraging the power of AI, manufacturers can optimize **supply chain management**. AI algorithms analyze vast amounts of supply chain data, including inventory levels, demand forecasts, and supplier performance, to optimize the procurement process and reduce costs. *Furthermore, AI-powered demand forecasting algorithms can help manufacturers accurately predict future demand, allowing them to adjust production levels accordingly and avoid excess inventory or stockouts.*

AI applications also aid in **quality control** by monitoring and analyzing production processes in real time. AI algorithms can analyze production data gathered from sensors, identifying deviations from normal operating conditions and signaling potential issues that require immediate attention. *The ability to detect anomalies and deviations in real time enables manufacturers to promptly address quality concerns and prevent defective products from reaching customers.*

| Company | Cost Reduction (%) |

|---|---|

| Company P | 15% |

| Company Q | 10% |

| Company R | 20% |

In conclusion, AI applications in manufacturing have the potential to transform the industry by optimizing operations, improving product quality, reducing costs, and streamlining supply chain processes. With continued advancements in AI technologies, manufacturers can unlock new opportunities for growth and stay competitive in a rapidly evolving market.

Common Misconceptions

Misconception 1: AI will replace human workers in manufacturing

One common misconception surrounding the application of AI in manufacturing is that it will lead to the complete replacement of human workers. However, this is simply not the case. While AI can automate repetitive and mundane tasks, it cannot replace the creativity, problem-solving skills, and adaptability that humans possess.

- AI can enhance human workers’ capabilities by automating repetitive tasks

- Humans are still vital for decision-making, complex problem-solving, and oversight

- AI can create job opportunities by driving innovation and enabling new roles

Misconception 2: AI is too expensive for small manufacturers

Another misconception is that AI is only accessible and affordable for large manufacturers with significant financial resources. However, the truth is that AI technology is becoming increasingly affordable and scalable, making it accessible to small and medium-sized manufacturers as well.

- There are AI solutions available that cater specifically to the needs and budgets of small manufacturers

- AI implementation can lead to cost savings in the long run through increased efficiency

- AI can help small manufacturers compete with larger counterparts by improving productivity and product quality

Misconception 3: AI in manufacturing is fully autonomous and requires no human involvement

There is a misconception that AI implementation in manufacturing results in fully autonomous systems that require no human involvement. However, AI applications in manufacturing usually require a combination of AI-driven automation and human oversight and intervention.

- Human oversight is necessary to ensure the accuracy and reliability of AI systems

- Human involvement is crucial for handling exceptions, unexpected situations, and complex decision-making

- AI and human collaboration can result in improved efficiency and productivity

Misconception 4: AI in manufacturing is only relevant for large-scale production

Some people believe that AI is only applicable and beneficial for large-scale manufacturing operations. In reality, AI can be leveraged in manufacturing across various production scales, from small-scale custom production to large-scale mass production.

- AI can optimize production processes and improve quality control in small-scale manufacturing

- AI can enable customization and flexibility even in large-scale manufacturing

- The scalability of AI systems allows manufacturers of all sizes to benefit from their implementation

Misconception 5: AI in manufacturing is a recipe for job losses

There is a common fear that the introduction of AI in manufacturing will lead to widespread job losses. While it is true that some tasks may be automated, AI can also create new job opportunities and enhance job roles rather than replacing them entirely.

- AI implementation can lead to the creation of new roles specifically related to managing and maintaining AI systems

- AI can free up human workers to focus on more value-added tasks that require creativity and problem-solving skills

- The role of human workers may shift from manual labor to more strategic and decision-making positions

1. AI-Powered Quality Control

In manufacturing, maintaining high product quality is of utmost importance. AI is being increasingly used in quality control processes to enhance accuracy and efficiency. By analyzing real-time data and integrating computer vision technology, AI can detect defects, inconsistencies, or abnormalities in production lines, ensuring that only the highest-quality products reach the market.

2. Predictive Maintenance Optimization

Unplanned downtime can result in significant losses for manufacturing plants. AI algorithms can analyze historical data, sensor readings, and machine operation patterns to predict when maintenance should be performed. By preventing breakdowns and optimizing maintenance schedules, AI-driven predictive maintenance minimizes downtime and maximizes productivity.

3. Supply Chain Optimization

AI can optimize supply chains by predicting demand, controlling inventory levels, and identifying potential disruptions. By leveraging machine learning algorithms, manufacturers can improve efficiency, reduce costs, and ensure timely delivery of goods.

4. Intelligent Robotics

Using AI-enabled robots in manufacturing can greatly enhance automation. These intelligent robots can perform complex tasks with precision, adapt to changing environments, and collaborate safely with humans. By taking on repetitive or hazardous jobs, they improve productivity and reduce the risk of accidents.

5. Energy Consumption Monitoring

AI systems can monitor and optimize energy consumption in manufacturing facilities. By analyzing real-time data from sensors and energy meters, AI algorithms can identify patterns, recommend energy-saving measures, and optimize resource allocation, leading to cost savings and environmental benefits.

6. Inventory Management and Demand Forecasting

By analyzing historical data, market trends, and external factors, AI algorithms can accurately predict demand and optimize inventory levels. This helps manufacturers avoid stockouts, reduce inventory costs, and maximize customer satisfaction.

7. Process Optimization and Simulation

AI enables manufacturers to simulate and optimize production processes to achieve operational efficiency. By analyzing various factors such as equipment performance, workflow, and resources, AI algorithms can identify bottlenecks, optimize layouts, and minimize waste, ultimately improving overall productivity.

8. Product Design and Customization

AI plays a crucial role in product design and customization. By analyzing customer preferences, market trends, and performance data, AI algorithms can generate design recommendations and assist in creating personalized products. This allows manufacturers to meet diverse customer demands and enhance customer satisfaction.

9. Human-Computer Collaboration

AI applications in manufacturing aim to enhance human-computer collaboration. Through natural language processing and computer vision, AI systems can understand and respond to human input, leading to better communication and interaction between humans and machines in manufacturing processes.

10. Fault Detection and Predictive Analytics

AI-powered fault detection systems effectively analyze sensor data, identify anomalies, and predict potential failures in manufacturing equipment. By detecting issues early, manufacturers can prevent costly breakdowns, reduce maintenance costs, and improve overall equipment effectiveness.

In recent years, the use of AI in manufacturing has revolutionized various aspects of the industry. From quality control and predictive maintenance to supply chain optimization and product customization, AI-driven technologies bring significant improvements in efficiency, productivity, and cost-effectiveness. By leveraging AI capabilities, manufacturers can achieve greater accuracy, automation, and decision-making capabilities, ultimately driving innovation and providing a competitive edge. With further advancements and integration of AI, the future of manufacturing holds immense potential for enhanced operations and increased profitability.

Frequently Asked Questions

What is AI application in manufacturing?

AI application in manufacturing refers to the use of artificial intelligence technologies to optimize and automate various processes in manufacturing industries. These technologies include machine learning, computer vision, robotics, and natural language processing.

How does AI improve manufacturing processes?

AI improves manufacturing processes by analyzing massive amounts of data, identifying patterns and anomalies, predicting equipment failures, optimizing production schedules, and automating repetitive tasks. This leads to improved efficiency, reduced downtime, lower costs, and higher product quality.

What are some examples of AI application in manufacturing?

Examples of AI application in manufacturing include predictive maintenance, where AI algorithms can analyze sensor data to predict machine failures and enable proactive maintenance. Other examples include quality control using computer vision to detect defects, autonomous robots for material handling, and AI-powered demand forecasting for efficient production planning.

Is AI application in manufacturing limited to large companies?

No, AI application in manufacturing is not limited to large companies. While larger companies may have more resources to invest in AI, there are also AI solutions available that are affordable and scalable for small and medium-sized manufacturers. Many AI tools are designed to be flexible and adaptable to various production environments.

Is AI replacing human workers in manufacturing?

AI is not necessarily replacing human workers in manufacturing, but rather augmenting their capabilities. AI technologies can automate repetitive and mundane tasks, allowing workers to focus on more complex and creative tasks. Additionally, AI can help improve worker safety by handling dangerous tasks or providing real-time insights.

What are the challenges in implementing AI in manufacturing?

Challenges in implementing AI in manufacturing include data quality and availability, integration with existing systems, resistance to change, and ensuring the security and privacy of sensitive data. It is important for manufacturers to carefully plan and execute their AI strategies, involving stakeholders and identifying potential risks.

Are there any ethical considerations in AI application in manufacturing?

Yes, there are ethical considerations in AI application in manufacturing. These include issues related to data privacy, bias in AI algorithms, job displacement, and the impact of AI on society. It is crucial for manufacturers to be conscious of these ethical considerations and implement appropriate safeguards and regulations.

How can manufacturers get started with AI implementation?

Manufacturers can get started with AI implementation by first identifying specific pain points or areas where AI can bring improvements. They can then explore available AI solutions, evaluate vendors, and conduct small-scale pilots or proof-of-concept projects. It is important to have a clear understanding of the business goals and expected outcomes before diving into AI implementation.

What are the benefits of AI application in manufacturing?

The benefits of AI application in manufacturing include increased productivity, improved efficiency, reduced costs, enhanced product quality, predictive maintenance to minimize downtime, optimized supply chain management, and better decision-making through data-driven insights. AI can help manufacturers gain a competitive edge in the global market.

What is the future of AI in manufacturing?

The future of AI in manufacturing is promising. As technology advances, we can expect increased integration of AI throughout the manufacturing value chain. AI will enable more personalized and efficient production, improved sustainability through optimized resource utilization, and the development of new business models. Manufacturers should embrace AI as a transformative tool for their operations.