AI Applications in Manufacturing

In recent years, artificial intelligence (AI) has become increasingly prevalent in various industries, including manufacturing. With its ability to analyze complex data and automate processes, AI offers several applications that can greatly enhance efficiency and productivity in the manufacturing sector. This article explores the key uses of AI in manufacturing and the benefits it provides to businesses.

Key Takeaways:

- Artificial intelligence (AI) is transforming the manufacturing industry.

- AI applications in manufacturing include predictive maintenance, quality control, and demand forecasting.

- Implementing AI in manufacturing can optimize operations and increase efficiency.

1. Predictive Maintenance

Predictive maintenance is one of the most significant applications of AI in manufacturing. By using machine learning algorithms to analyze sensor data from equipment, AI can predict when a machine is likely to fail, allowing for proactive maintenance. This approach can minimize unplanned downtime and reduce maintenance costs.

AI in predictive maintenance can save manufacturers up to 12% a year in maintenance costs.

2. Quality Control

AI can also greatly improve quality control processes in manufacturing. By analyzing data from various sources, such as sensors and cameras, AI algorithms can detect defects and anomalies in real-time. This enables early identification of quality issues, reducing waste and improving overall product quality.

With AI-enabled quality control systems, manufacturers can increase defect detection rates by up to 90%.

3. Demand Forecasting

Accurate demand forecasting is crucial for manufacturing companies to optimize production schedules and inventory management. AI algorithms can analyze historical sales data, market trends, and external factors to predict customer demand with greater accuracy. This enables manufacturers to adjust their production levels accordingly and avoid overstocking or understocking.

AI-powered demand forecasting systems can improve forecast accuracy by up to 30%.

Tables:

| AI Application | Benefits |

|---|---|

| Predictive Maintenance | Minimizes unplanned downtime and reduces maintenance costs |

| Quality Control | Increase defect detection rates and improve overall product quality |

| Demand Forecasting | Optimize production schedules and inventory management |

| AI Implementation | Cost Savings |

|---|---|

| Predictive Maintenance | Up to 12% reduction in maintenance costs |

| Quality Control | Up to 90% increase in defect detection rates |

| Demand Forecasting | Up to 30% improvement in forecast accuracy |

Benefits of AI in Manufacturing

- Improved Efficiency: AI automates repetitive tasks, allowing manufacturing processes to be completed faster.

- Enhanced Product Quality: AI-powered quality control systems can identify defects and anomalies with higher accuracy, improving overall product quality.

- Cost Savings: Predictive maintenance and optimized inventory management through AI can help reduce maintenance and inventory costs.

- Increased Productivity: AI applications optimize production schedules and resource allocation, maximizing productivity in manufacturing facilities.

- Competitive Advantage: By leveraging AI, manufacturers can stay ahead of competitors by streamlining operations and delivering superior products.

Conclusion

Artificial intelligence is revolutionizing the manufacturing industry, providing numerous benefits such as improved efficiency, enhanced quality control, cost savings, increased productivity, and a competitive advantage. By embracing AI applications, manufacturers can optimize their operations and stay ahead in an increasingly competitive global market.

Common Misconceptions

Misconception 1: AI will replace human workers in manufacturing

One common misconception about AI applications in manufacturing is that AI will replace human workers entirely. However, this is not necessarily the case. While AI can automate certain tasks and improve efficiency, it is unlikely to completely eliminate the need for human workers.

- AI can help human workers in performing repetitive and mundane tasks

- Human workers are still vital for decision-making, complex problem-solving, and creativity

- Collaboration between AI and human workers can lead to better productivity and innovation

Misconception 2: AI lacks the capability to handle complex manufacturing processes

Another misconception is that AI is not capable of handling complex manufacturing processes. However, advancements in AI technology have made it possible for AI systems to handle intricate processes and make intelligent decisions.

- AI can analyze and process vast amounts of data in real-time, enabling it to optimize complex production systems

- Machine learning algorithms can enhance AI’s ability to learn and adapt to different manufacturing scenarios

- AI can identify patterns and anomalies in production data, leading to improved quality control

Misconception 3: AI applications in manufacturing are only suitable for large-scale companies

Some people believe that AI applications in manufacturing are only suitable for large-scale companies with extensive resources. However, AI can be beneficial for businesses of all sizes, including small and medium-sized enterprises (SMEs).

- AI solutions can be customized to fit the specific needs and budget of any manufacturing company

- SMEs can use AI for tasks such as predictive maintenance, demand forecasting, and inventory optimization

- Cloud-based AI platforms make it easier for SMEs to access and implement AI applications without significant upfront investment

Misconception 4: AI applications in manufacturing are not reliable or accurate

There is a misconception that AI applications in manufacturing are not reliable or accurate. However, when properly implemented and trained, AI can achieve high levels of reliability and accuracy in various manufacturing processes.

- AI algorithms can learn from vast amounts of historical manufacturing data, leading to improved accuracy in predicting failures or defects

- AI can continuously adapt and improve its performance through machine learning, ensuring reliability over time

- With proper data validation and quality control, AI applications can achieve high levels of accuracy in tasks such as quality inspection and predictive maintenance

Misconception 5: AI applications in manufacturing are expensive and difficult to implement

Lastly, there is a misconception that AI applications in manufacturing are expensive and difficult to implement. While there can be upfront costs and implementation challenges, the benefits and potential cost savings that AI can bring make it a worthwhile investment.

- Advancements in AI technology have led to the availability of affordable and off-the-shelf AI solutions for manufacturing

- AI implementation can result in long-term cost savings through improved efficiency, reduced downtime, and better resource allocation

- Collaborating with AI vendors or consultants can help manufacturers navigate the implementation process and overcome challenges

AI Applications in Manufacturing

Manufacturing industries are rapidly adopting AI technologies to streamline processes, improve efficiency, and enhance decision-making. The applications of AI in manufacturing are diverse, ranging from predictive maintenance to quality control. This article highlights ten fascinating examples that showcase the innovative potential of AI in manufacturing settings.

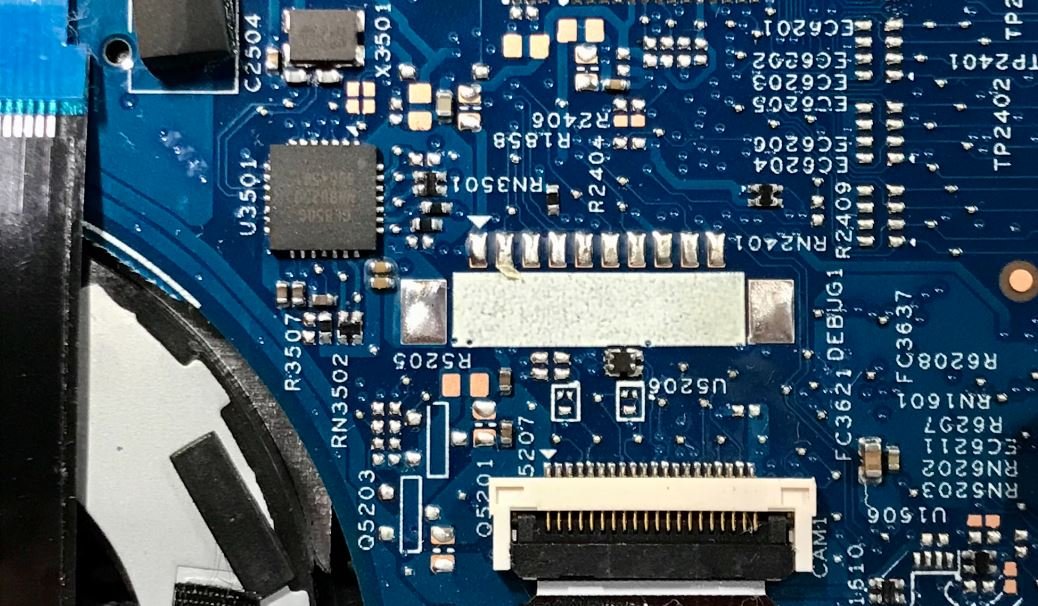

Predictive Maintenance for Machinery

Predictive maintenance utilizes AI algorithms to monitor machinery health and predict maintenance needs. By collecting data on vibration, temperature, and other parameters, AI systems can detect potential issues before they cause a breakdown, enabling proactive maintenance to minimize downtime.

Visual Inspection Automation

AI-powered computer vision systems can automatically inspect products to identify defects, anomalies, or quality issues. These systems use machine learning to recognize patterns and learn from examples, significantly reducing human error and improving inspection accuracy.

Optimizing Energy Consumption

AI algorithms analyze energy usage patterns within manufacturing facilities and identify opportunities for optimization. By providing real-time insights and recommendations, AI systems help organizations reduce energy consumption, cut costs, and enhance sustainability efforts.

Quality Control in Production Lines

AI-based quality control systems monitor production lines in real-time, automatically identifying defective items and initiating corrective actions. By ensuring consistent product quality, these systems minimize waste, improve customer satisfaction, and enhance overall manufacturing efficiency.

Supply Chain Management Optimization

AI-powered supply chain management systems enable organizations to optimize inventory levels, track shipments in real-time, and predict demand fluctuations. By integrating data from various sources, these systems help improve supply chain responsiveness and reduce costs.

Process Optimization in Assembly Lines

AI algorithms analyze data from assembly line sensors and equipment to identify bottlenecks, inefficiencies, and opportunities for process optimization. By automatically adjusting parameters or suggesting procedural improvements, AI systems enhance productivity and reduce waste.

Autonomous Forklifts for Material Handling

AI-driven autonomous forklifts use machine learning and sensor technologies to navigate warehouses, retrieve, and transport goods efficiently. These self-driving vehicles not only improve operational efficiency but also enhance workplace safety by minimizing the risk of accidents.

Demand Forecasting for Production Planning

AI algorithms analyze historical sales data, market trends, and other relevant parameters to forecast future demand accurately. This information helps manufacturers optimize production planning, minimize inventory levels, and align production capacities with customer needs.

Smart Inventory Management

AI-enabled inventory management systems optimize stock levels by analyzing historical sales data, current demand, and other factors. By ensuring the availability of products while minimizing excess inventory, these systems reduce costs and improve customer satisfaction.

Real-Time Performance Monitoring

AI-based systems monitor production line performance in real-time, analyzing data from sensors, equipment, and other sources. By providing actionable insights and alerts, these systems enable quick decision-making and help proactively address potential issues, enhancing overall productivity.

Conclusion

The integration of AI into manufacturing processes revolutionizes the industry, providing advanced capabilities that drive efficiency, improve product quality, and reduce costs. From predictive maintenance to real-time performance monitoring, the applications of AI in manufacturing are diverse and impactful. As technology continues to advance, AI will play an increasingly essential role in shaping the future of manufacturing.

Frequently Asked Questions

What is AI?

AI, or Artificial Intelligence, refers to the development of computer systems that can perform tasks that typically require human intelligence, such as visual perception, speech recognition, decision making, and problem-solving.

How is AI used in manufacturing?

AI plays a crucial role in manufacturing by automating processes, improving quality control, optimizing production, predicting maintenance needs, analyzing data for action, and enabling smart robotic systems. It helps manufacturers make smarter decisions and gain a competitive edge in the industry.

What are some specific applications of AI in manufacturing?

AI is widely used in manufacturing for applications such as predictive maintenance, quality control, supply chain optimization, virtual assistants for workers, robotic process automation (RPA), demand forecasting, resource scheduling, anomaly detection, optimizing energy usage, and product design.

What are the benefits of using AI in manufacturing?

The benefits of using AI in manufacturing include increased efficiency and productivity, improved product quality, reduced downtime and maintenance costs, enhanced worker safety, better supply chain management, faster decision-making, cost savings, and innovation in product development.

What challenges are associated with implementing AI in manufacturing?

Some challenges associated with implementing AI in manufacturing include high initial investment costs, lack of skilled personnel, data security concerns, integration complexities, resistance to change from employees, cultural challenges, maintaining ethical use of AI, and ensuring transparent decision-making processes.

How does AI improve predictive maintenance in manufacturing?

AI uses machine learning algorithms to analyze real-time data from sensors, equipment, and historical maintenance records to predict potential equipment failures, detect anomalies, and recommend proactive maintenance actions. This helps manufacturers prevent breakdowns, minimize downtime, and reduce maintenance costs.

Can AI help optimize supply chain management in manufacturing?

Yes, AI can optimize supply chain management in manufacturing by analyzing vast amounts of data related to demand forecasting, inventory levels, production capacity, logistics, and customer preferences. It enables manufacturers to make data-driven decisions, reduce lead times, improve inventory management, and enhance overall supply chain efficiency.

How can AI improve product design in manufacturing?

AI can improve product design in manufacturing by utilizing algorithms to analyze customer feedback, market trends, and historical data to generate innovative design solutions. It helps in creating better product concepts, reducing development time, optimizing design for manufacturability, and enhancing overall product performance and customer satisfaction.

What role does AI play in smart robotic systems in manufacturing?

AI plays a crucial role in enabling smart robotic systems in manufacturing by providing capabilities such as computer vision for object recognition, path planning, autonomous navigation, collaborative robotics, and adaptive control. It allows robots to perform complex tasks, collaborate with humans, and adapt to changing environments, leading to increased automation and efficiency.

Is AI expected to replace human workers in manufacturing?

No, AI is not expected to replace human workers in manufacturing. Instead, it is designed to augment human capabilities, automate repetitive tasks, and enhance productivity. AI can free up human workers to focus on more complex and creative aspects of manufacturing while providing support and assistance through intelligent systems.